CAST ALUMINUM SIGN LETTERS AND NUMBERS

Brushed - Anodized - Painted - Bead Blasted

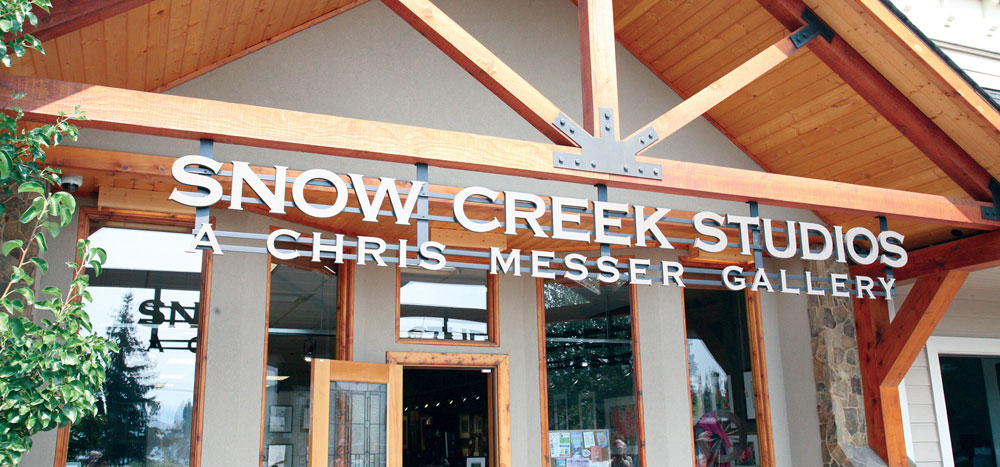

cast aluminum sign letters at snow creek studios

Cast Aluminum Letters and Numbers for Sign Making

Helvetica font, ABC in Brushed Aluminum

Custom Cast Aluminum Letters & Numbers for Signage

Above: 8" and 12" cast aluminum Copperplate with brushed finish.

Elevate your space with our exquisite custom-made aluminum letters and numbers, meticulously crafted from high-quality aluminum ingots. Each piece is poured into bespoke sand molds, ensuring a unique and durable construction that stands out in any environment. Our cast aluminum letters not only provide impressive depth, enhancing the visual appeal, but they also offer a cost-effective alternative to traditional sheet-cut letters.

Available in a remarkable range of sizes, from a petite 2 inches to a commanding 24 inches tall, with depths varying from a sleek 3/8 inch to a robust 2 inches, these letters are designed to suit any application, whether it’s for signage, home decor, or artistic installations. The versatility in design extends to font selection as well; we can create letters in most fonts, allowing you to bring your creative vision to life.

Above: 15" & 6" custom cast aluminum painted black

The finishing touches on our letters and numbers are a testament to our commitment to quality. Each piece is hand-sanded to achieve a smooth, refined surface that feels as good as they look.

PRODUCTION LEAD TIMES

Products usually ship in 10-12 working days from the Iowa Plant

Cast Aluminum Sign Letter Finish Options

Brushed Aluminum Texture, Dime illustrates reflectivity

Standard Finishes - click to see larger image

Brushed Anodized Finishes

Why Cast vs Cut Metal Letters? Cast letters offer more depth for the same cost. When compared to 1/4" cut sheet metal letters, a cast letter is often 4 times thicker and costs the same or less! This is due the manufacturing process where cast letters are usually hollow in the back so you are not paying for all that solid metal you never see. Every order comes with a full size installation pattern at no extra cost and carries a manufacturer lifetime warranty. Shipped in 10 working days from one of 5 different plants in the USA. Our aluminum letters are 100% recyclable made in the USA

INDOOR OR OUTDOOR USE.

BASE PRICE FOR CAST ALUMINUM LETTERS

Graphical logo prices are different from letter prices. Select the overall dimensions of your logo to get a base price. The base price includes up to 30 parts that make up the entire logo. Price includes your choice of mounting hardware and the installation pattern. Logos over 48" contact us for quote.

Brushed or Painted Price: $196.00

Mounting Hardware

FLUSH MOUNT

Use this when mounting your letters flush to a flat surface. Whether it be drywall, brick, concrete, cinder block or wood, this is the most popular mount. Stud length for exterior use should be 2 inches in the wall. For drywall use, 1 inch is sufficient. Standard will be the factory choice based on the letter size.

PROJECTED JAMB NUT MOUNT

If you are mounting to an uneven surface, perhaps lap siding, metal corrugated building or rock, this mount allows adjustability. Essentially, the stud (threaded rod) get 2 nuts wound on to them and can be tightened against each other at a desired distance down the stud. By doing this the studs will only go into the wall up to where they are stopped by the nuts. This allows adjustability on all points of the studs. The image at left shows 3 possible configurations when mounting to a wall, a metal corrugated building or a flat metal plate or wall.

PROJECTED SPACER

A spacer is an aluminum tube of various selectable size which slips over the stud providing a standoff from the wall surface. This is a uniform distance so if you wanted your letter to stand away from the wall surface by 1 inch then that is the spacer length you should select. The stud length should also be selected so that with a 1 inch standoff and 2 inches of stud in the wall surface, you will need a 3 inch stud. The further you stand the letter away, the more stud you should have in the wall to counteract the weight of the letter.

STUDS IN EDGE

Bottom stud, top or even both. Tapped holes in the edge of the letters for mounting in a vertical configuration. Couple of things to consider here. Letters have to be at least 3/8" thick to drill the holes and the letters have a minimum height of 4" -BUT- that minimum is font AND letter dependent since many fonts will not have wide enough strokes to allow the drilling and tapping without it coming all the way out the other side(consider an "O" for instance).

RAIL MOUNT ON EDGE

A rail is mounted to the top, bottom or both edges to allow for mounting stand up or hanging. Depending on letter sizes this mount may not be enough on it's own and require tie backs or framework if used outdoors.

BACK RAIL MOUNT

Mostly used for installation on metal corrugated buildings. It does detract from the look of the sign and is considered old school. In today\'s world a metal conduit raceway from home depot would look better to mount your letters too and they come ready finished. That being said we offer the double rail mount in maximum 8ft lengths and the rails are pre drilled to accept the letters ordered with screws that go through the rail into the letters.

ANGLE BRACKET MOUNT

Angle bracket is mounted to a flat surface like a roof parapet and the letters are attached to the rail at the bottom only. This mount will require tie backs if outside and over 8" letter height.

100% USA MADE - When ordering our products you are supporting American workers, their families and American Manufacturing.

All our products carry a lifetime manufacturer warranty. That means that should a product fade, break or contain any defect, the manufacturer will refinish or replace the defective materials at no cost to you, as long as the product is installed in its original location. For warranty claims please email us or use our contact form. We will pass your claim onto the plant for their consideration

All products are designed to last a lifetime. All our materials and finishes are tested in many environmental conditions. We refine our coating technology, and deliver a product that we know will last much longer than the life of any other product you may install. From experience in the field and from our test lab results, we know that our products will last in excess of 10 years without any noticeable degradation in appearance. We know, from many installations around the world, that many of our products last longer than that.

Please note that warranties are limited and do not cover embedding letters in concrete or using interior products in outdoor projects.

Need help with a custom Project?

Request A Quote

We provide one on one help for your sign project absolutly free of charge. We can help you with dimensioning of your sign to fit the space and provide art proofs and pricing as needed. We are skilled in vector artwork using Adobe Illustrator and Photoshop. How can we help you?